The average life expectancy of a solar panel is about 30 years. However, depending on the quality of the panel, the elements it’s been exposed to, and how well it’s been maintained, it might last well beyond the three decade mark. Being a relatively new technology with such a long lifespan brings up some interesting issues, such as what to do about disposal and how to recycle them efficiently. Organizations and governmental entities with a view to the future are working on ways to extend the lifespan of panels while also developing systems and regulations that guide recycling and disposal programs.

Lifespan of a Solar Panel

Solar panels are tough and can take a lot of abuse, but being exposed to the elements day in and day out can take its toll on the panel, not to mention the entire system.

Rain can cause corrosion both inside and outside of the module – from the glass to the cell material – ultimately reducing power output. Humidity can also cause decomposition of the material that encases the solar cells as well as the backsheet, which is a sealant and a form of protection from DC voltage. Rain can lead to corrosion of the metal framing, compromising safety if the grounding is no longer ensured.

Ultraviolet, infrared, and visible rays from the Sun can result in discoloration or yellowing of the panel reducing power output. It can also increase brittleness, meaning moisture can permeate the panel faster. High heat can cause cracks, opening of soldering points, and sun outages from the sun’s radiation overwhelming the panel. High temperatures can also lead to degradation of the sealant, backsheet, glass, and more, reducing power output and creating safety issues.

While the wind may seem harmless, it can have negative effects on the panels and the entire system. The wind, if powerful enough, can break the bond between the cell and the solder, vibrate the entire system and damage underlying construction, or even break the panel’s glass.

Many consumers are concerned about the power production of a panel when it snows. While solar experts don’t see this as a problem, what can cause concern is snow’s impact on the panel over time. Due to the extreme temperature of snow and ice, they can cause cell breakage, bending of the frame parts due to icing, and even glass breakage.

Anatomy of a Solar Panel Failure

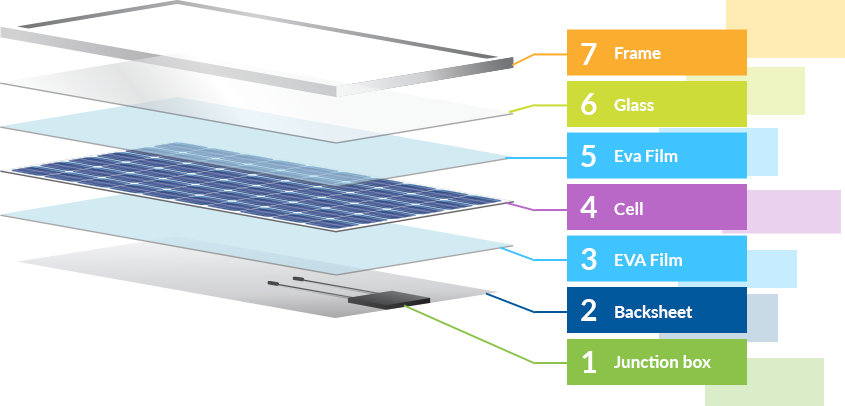

A junction box housing all the wiring interconnections for the panel helps to hide the wires from sight and to keep them from being tampered with. Lavrova notes that panels will stop supplying energy if there is an opening in the wiring of the circuit or an opening in one of the connectors. Since panels are often connected in one long string, if there is an opening in one wiring connector, you will lose power in the whole string, like holiday lights often do. However, people have designed electrical wiring diagrams where if one connector goes down, the rest will still provide power.

A number of different problems associated with the EVA film can impact the backsheet of a panel. Delamination, a process where the thin parchment-like EVA film starts to separate from the glass and backsheet, allows air and moisture inside the panel resulting in corrosion. This can occur if the EVA is not cured correctly during the lamination process. Browning is a discoloration of the EVA film and occurs when certain additives (used to prevent browning and improve UV resistance) start to disappear if stored or handled improperly. This can lead to bleaching and bubble formation at the EVA and backsheet, again resulting in cell corrosion. Extreme high temperatures found in places like Las Vegas, or high levels of humidity found in cities like Florida, can also lead to degradation, cracking, and surface erosion of the backsheet over time.

A number of different problems associated with the EVA film can impact the backsheet of a panel. Delamination, a process where the thin parchment-like EVA film starts to separate from the glass and backsheet, allows air and moisture inside the panel resulting in corrosion. This can occur if the EVA is not cured correctly during the lamination process. Browning is a discoloration of the EVA film and occurs when certain additives (used to prevent browning and improve UV resistance) start to disappear if stored or handled improperly. This can lead to bleaching and bubble formation at the EVA and backsheet, again resulting in cell corrosion. Extreme high temperatures found in places like Las Vegas, or high levels of humidity found in cities like Florida, can also lead to degradation, cracking, and surface erosion of the backsheet over time.

Solar cells are designed to function in full sunlight. When they are partially shaded, the cell or group of cells experience little to no current flow (reverse bias). This leads to overheating of the cell that can result in the solder melting and the EVA and backsheet becoming damaged. Browning and delamination can also cause corrosion of the cell.

A number of different problems associated with the EVA film can impact the backsheet of a panel. Delamination, a process where the thin parchment-like EVA film starts to separate from the glass and backsheet, allows air and moisture inside the panel resulting in corrosion. This can occur if the EVA is not cured correctly during the lamination process. Browning is a discoloration of the EVA film and occurs when certain additives (used to prevent browning and improve UV resistance) start to disappear if stored or handled improperly. This can lead to bleaching and bubble formation at the EVA and backsheet, again resulting in cell corrosion. Extreme high temperatures found in places like Las Vegas, or high levels of humidity found in cities like Florida, can also lead to degradation, cracking, and surface erosion of the backsheet over time.

Lavrova notes that the tempered glass used on the face of the panel is similar to the windshield of a car. It is extremely durable and designed to protect the heart of the panel – the semiconductor material – and provide the panel with structural integrity. Tested against standards developed by the International Electrotechnical Committee, an international standardization organization, the glass on panels need to withstand hail, wind, small metal fragments, etc. Lavrova said that the biggest threat to solar panels is in fact, children throwing rocks and extraordinarily harsh weather events. Should a panel be cracked, this can lead to moisture penetrating the panel.

Lavrova notes that before a panel can go onto the market in the U.S., Europe and other developed countries, they go through extensive testing where the panels are bombarded with hail and metal particles of a particular weight. However, children throwing rocks or extraordinary hail or windstorms can cause significant damage. Hail or rocks that hit a frame can end up bending the frame that can then crack the glass on the panel. Loose frames can also threaten the safety of the glass.Glass

A 2014 study by the International Energy Agency looked into the reasons behind solar panel failures. Infant-failure, when the panel is 1 to 2 years old, is usually attributed to the manufacturer or the installer. Failures include:

-

Transportation damages

-

Junction-box failures

-

Glass breakage

-

Poor cell interconnectivity

-

Loose frame

-

Delamination

Mid-life failure occurring 8 to 12 years after installation shows a high rate of defects and failures with interconnection, junction-box and wiring, burn marks on cells, and the EVA film. Wear-out failure typically occurs 15 years after installation and takes place when there is a safety problem or power production drops between 80 and 90 percent of the initial power rating. The most common reason for failure is delamination, cell cracks, and discoloring of the laminate. In the study failures led to an average power loss of 10 percent meaning the panels were still producing electricity at a high-capacity and with advances in technology these failures, across the lifecycle of the panel, will become less and less common.

LID: light-induced degradation

PID: potential induced degradation

EVA: ethylene vinyl acetate

j-box: junction box

Source: International Energy Agency, Review of Failures of Photovoltaic Modules

R&D: Increasing Solar Panel Lifespan

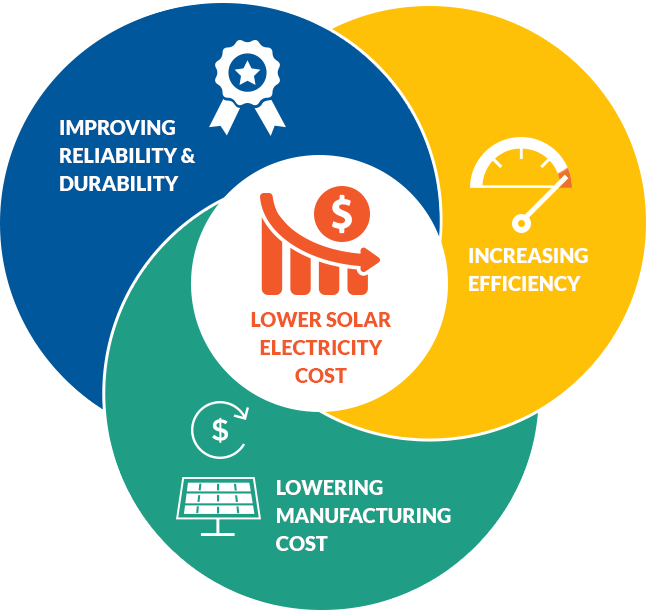

Imagine solar-generated electricity being cost competitive, minus subsidies, with conventional electricity sources. The U.S. Department of Energy’s SunShot Initiative is seeking to achieve just that. If the Initiative is successful, the National Renewable Energy Laboratory (NREL) estimates that by 2030, 14 percent of the nation’s energy will be generated by solar, as compared to the marginal 1 percent produced in 2015.

To become cost competitive the initiative has set different price targets for utility, commercial and residential sectors. Utility scale solar must be 6 cents per kWh for a location having only a moderate solar resource. Commercial and residential sectors are set at targets of 7 and 9 cents per kWh, respectively.

Sandia National Laboratories manages the five Regional Test Centers (RTCs) established by the SunShot Initiative. They’ve identified key factors that can decrease costs. These include module prices, hardware and labor costs, financing rates, operating and maintenance expenses, and module efficiency. Another contributing factor is improved reliability and lifetime that increases energy output over the system’s lifespan and reduces financing rates by ensuring bankability on performance.

Source: U.S. Department of Energy, SunShot

To improve durability, scientists and engineers need to decrease the rate of annual degradation. One study funded by the DOE looked at 11,000 different rates of degradation from almost 200 studies across 40 countries. What they discovered was an average rate of 0.5 to 0.6 percent per year for silicon panels and even 1 percent for thin-film products. The study also discovered that even if the rate of degradation is low when the panel is new, that rate can increase over the panel’s lifetime, especially if it is exposed to hotter climates and dirtier conditions.

At RTCs panels are tested in different climates and settings to ensure their durability. Researchers at RTCs are looking for ways to decrease the degradation rate to 0.2 percent, which would allow the panels to last 50 years or more. Increasing a panel’s lifecycle from the current 30-year average by 20 years, according to Sandia Labs, will constitute a 42 percent reduction in the levelized cost-of-energy (LCOE), effectively helping solar costs go down to 6 cents per kWh, making it competitive with traditional sources of energy.

Quantifying Durability: Solar Panel Test Centers

Sandia National Laboratories is contracted to manage the U.S. Regional Test Centers (RTCs) for the SunShot Initiative. RTCs are a network of five sites across the nation where solar panel technologies can be tested in a variety of climates and settings. Testing product performance increases the validity and bankability of emerging technologies. Increased confidence in the energy production can bring down financing costs, help communities embrace new technologies, and spur innovations in solar development.

Managed by the

Southern Nevada

Water Authority, this desert climate tests in a hot, arid environment.

In an arid, hot climate, this test

center is at the National Solar Thermal Test Facility at Kirtland Air Force Base.

At the University of

Central Florida and

managed by the Florida Solar Energy Center, this RTC provides a tropical environment.

Testing in a harsh winter environment, this facility is located at an IBM campus.

In an arid, high altitude climate, this

facility is

managed by the National Renewable Energy Laboratory at the SolarTAC technology acceleration facility.

Recycling Solar Panels

Solar panels typically last between 20 to 30 years with many producing energy beyond that timespan. Lavrova notes that many systems installed as early as the 1970s are still producing power, albeit a little less than when they were brand new. In fact, Lavrova says the real risk to durability are things like rocks being thrown at the panel, lightning striking the panel, extraordinary wind gusts or hail storms. Inverters are also durable, with a lifetime spanning about 10 years. Meaning nearly all solar panels in the U.S. have a while before they need replacing. Without a significant amount of waste generated, recycling programs that deal with solar equipment bound for the landfill have yet to be fully developed.

Recycling systems align with the environmentally conscious aspect of clean, renewable energy. Simply throwing the system in the trash is harmful to the environment with panels often being manufactured using toxic materials. Many materials in a system are re-usable including:

Inverters and wiring can also be recycled for their plastics. PV CYCLE notes that it can recycle 90 percent of a silicon-based panel.

The Solar Energy Industries Association (SEIA) is currently engaged in creating collection and recycling processes that promote safe and efficient recycling models. According to the SEIA, several of their members currently operate take-back and recycling programs or coordinate with the appropriate waste handlers and disposers. The Federal Resource Conservation and Recovery Act (RCRA) along with state policies govern the disposal of solar products in the U.S. So while there are no current federal regulations specifically governing the recycling of solar panels, they might still be considered “hazardous waste” by other federal and state regulations and must be disposed of accordingly.

While solar-specific recycling is not yet common, some companies are gearing up for what will potentially be a deluge of end-of-life solar arrays in the coming years. One such company, PV CYCLE, serves countries across Europe with waste management services for solar energy systems. According to their 2015 Annual Report, the company recycled more than 2,800 tons of PV module waste, a 33 percent increase over the previous year. As systems built between 1970 and 1980 reach their end, the global need for recycling will increase exponentially, especially with the increase in solar installations seen over the past 35 years.

Consumers needing to dispose of a solar system that has reached its end of life should review state and federal regulations to ensure compliance and environmentally sustainable practices. Some SEIA members adhere to environmentally responsible International Standardization Organization (ISO) management standards (ISO 1400 and ISO 2600) and can serve as a useful resource. Lavrova also suggests consumers explore the option of donating their solar system to a non-profit or community group in need.

-

Resources

-

The U.S. Department of Energy Regional Test Centers for Solar Technologies delivers independently validated performance data for solar PV technologies by testing in a variety of different climates and settings.

-

This online Information System for the European Strategic Energy Technology (SET) Plan supports the transformation of energy production and usage in the EU. The goal of the SET Plan is to attain EU worldwide leadership in the production of energy solutions capable of delivering EU 2020 and 2050 low-carbon targets.

-

Fraunhofer ISE is Europe’s largest solar energy research institute. The Institute conducts investigations of scientific and technological fundamentals for solar energy applications, develops production technology and prototypes, and constructs demonstration systems.

-

Based in Golden, Colorado, the National Renewable Energy Laboratory (NREL) serves as the U.S. DOE’s flagship center for solar and renewable energy research and development. NREL researchers uncover breakthroughs in fundamental science, new clean technologies, and integrated energy systems that power our lives.

-

The National Center for Biotechnology Information (NCBI) contributes to the National Institutes of Health (NIH) mission to uncover new knowledge. The NCBI conducts research and provides resources for genomic, genetic and biomedical data. The NCBI has conducted research into solar panel waste and the retrieval of important raw materials.